Many oil and gas companies that provide coiled tubing or hydraulic fracturing services usually have an in-house lab to test chemicals, optimize treatments, and provide support during field operations.

Even smaller oil and gas companies often rely on the lab by contracting third-party lab services to perform testing for them.

What Do You Need To Get a Job in a Lab?

In most cases, you will need a bachelor’s degree in chemistry or a similar field.

In addition to that previous experience or internship in the oil and gas industry can make it easier to get a job.

The Role of Chemical Laboratory in Oil and Gas

The lab is usually responsible for testing chemicals, fluids, and designing treatments for various completion and intervention operations.

Since hydraulic fracturing uses more chemicals than coiled tubing, it relies heavily on lab support.

Pre-job Fluid Testing

Work fluids are often tested before the operation to determine if they are suitable for the job.

Usually, the client will send a few pales of water to the lab for testing from the water source that will be used for the frac operation.

Related: Top 10 Chemicals Used In Hydraulic Fracturing Process

Common Fluid Tests

Salinity – often flow back fluid with high salt content is used for frac operations. Using heavy brine for the job might affect what chemicals are used and whether the fluid needs to be mixed with fresh water to lower the salt content.

pH – high and low pH fluid might hurt the performance of certain chemicals.

Bacteria testing – sometimes pre-job bacteria testing is performed to determine how much biocide is required for the job and whether the fluid needs to be pretreated in advance.

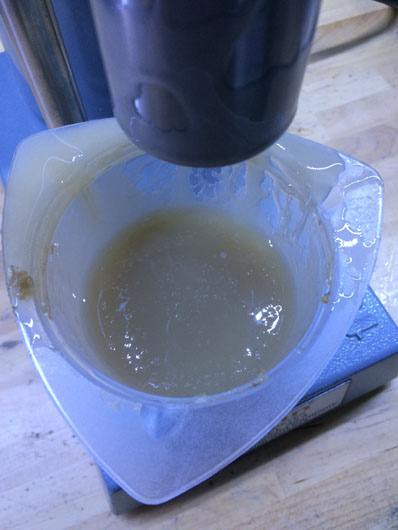

Gel testing – is performed to check that the gel can be created using the sample fluid sent by the client. In addition to gel testing, breaker tests are performed as well to ensure that the gel will eventually break down in the well.

Friction flow loop testing – to find optimal friction reducer loadings.

Water analysis – to check what minerals are in the water. This helps in determining if there is a potential for scaling and whether an anti-scaling agent should be pumped during the job. Dissolved carbonates and sulfates in the water are known to cause scaling in certain situations.

Read next: What is Hydraulic Fracturing?

Other Common Lab Roles

Finding alternative chemicals – when the chemicals typically used are not in stock, the lab might have to come up with a substitute that will do the job.

Performing chemical testing – often when the chemicals don’t perform as expected during the operation they are sent to the lab for evaluation.

Testing unknown well fluids and substances – sometimes after the completion or intervention operations, unknown substances might come up to the surface that needs to be evaluated to ensure that it was not caused by unexpected chemical reactions.

Chemical market research – finding new chemicals to improve efficiency and lower costs. Finding cheaper chemical alternatives can significantly decrease the costs of fracturing operations where large volumes of chemicals are required.

Designing acid blends – whenever acid is pumped lab usually designs a blend that will do the job without creating unwanted by-products or corroding equipment.

Frac programs review – the lab is also often involved in ensuring that the right chemicals and loadings are programmed for the job.

Supporting frac engineers and clients – often senior members of the lab team spend a lot of time with frac and coil engineers trying to find the best chemical solutions to various downhole problems. They also sometimes attend pre-job and post-job client meetings with sales and engineering members to provide support with chemical-related inquiries.

Related: What is Coiled Tubing?

What Field QCs Do During Frac Operations?

During hydraulic fracturing operations, lab chemists are often sent to the field to test chemicals and provide field support.

Common Frac QC Field Tests

Proppant testing – ensuring that the right size of sand is pumped.

Gel testing – testing the gel to ensure that it has the required viscosity as per the treatment schedule.

Chemical testing – ensuring that the right chemicals at the right concentrations are shipped by a supplier. There is always a chance that a chemical was mislabeled or moved in the wrong container. QCs also check to ensure that all the chemicals required for the job are available on location.

Providing Safety Data Sheets (SDS) – if a brand new chemical is used for the job the client and crew might require an updated SDS.

Checking the quality of the fluid – often during the job the quality of the fluid might change due to supply issues and QC might need to work with a lab to adjust chemical loadings that will work with the new fluid.

Calculating chemical volumes – often double-checking is required to ensure that chemicals are being pumped at the correct rate.

Checking the fluid temperature and pH – keeping the fluid at the right temperature is important during winter operations.

Updating chemical loading when treatment changes – providing support to the operations and client as needed. Some clients on location might not be fully familiar with the chemicals and they might have questions that QC can address better than a frac crew.