Coiled tubing cleanout operations involve running in the well with coiled tubing and removing sand and other debris.

The most common types of particles in the well that need to be removed are sand, wax, formation debris, proppant, or debris left in the well from previous well intervention operations such as plug milling.

Why Wellbore Cleanouts are Performed?

Cleanout operations with coiled tubing are often performed on older wells to remove sand and wax from the wellbore.

Large accumulations of debris and sand in the well can lower the production or even interfere with the operation of downhole well equipment.

Cleanouts are also sometimes performed during fracturing operations when there is a screen out where proppant creates some type of bridge across the perforation and accumulates in the wellbore instead of going into the formation.

Sometimes cleanouts are also performed on the wells with dissolvable plugs to ensure that plugs actually fully dissolved and to remove any debris left downhole after the fracturing operation.

Related: 18 Most Common Coiled Tubing Applications

Cleanout BHA and Fluid Requirements

One of the most important things when it comes to wellbore cleanouts is fluid velocity.

If the fluid returning to the surface doesn’t have enough velocity to lift the sand or other debris in the wellbore and bring it to the surface, the well will not be cleaned and there is a high potential of debris accumulation in the heel section of the well which can result in stuck coiled tubing.

This is especially common when two different types of casing sizes are used in the well with the vertical section being much larger in diameter than the horizontal.

An example of a challenging wellbore might be cleaning the well with a 3.5” horizontal section and a 7” vertical.

To increase fluid velocity during cleanout operations oftentimes large-size coiled tubing is used.

Typical cleanout bottom hole assembly (BHA) is made up of a connector, check valve, and nozzle.

However, depending on the type of debris expected in the well sometimes milling BHA is used instead.

In addition, if the well is long and there is a potential that coiled tubing might experience lock up before reaching the target depth agitation tool might be used to allow coiled tubing to get deeper in the well.

Related: Coiled Tubing Bottom Hole Assembly (BHA) Components

Example of Basic Coiled Tubing Cleanout Procedures

- Function test the BHA to make sure it works as expected.

- Start running in the hole while circulating fluid at minimum rates until coiled tubing enters the horizontal section.

- Increase the pump rate to ensure that all the debris is pushed into the vertical and then brought to the surface.

Usually, at this point, coiled tubing run-in hole speed is decreased to ensure proper cleaning of the wellbore and to avoid running into any obstructions.

- As coiled tubing continues to run in hole and clean the well it is very important to pay attention to the returns at the surface. If a very small amount of debris or sand is being produced, it might be worth performing extra wiper trips to ensure that there is no debris accumulation behind the BHA that can lock up the coil on the way out of the hole.

Some coiled tubing companies also like to pump gel pills to help lift the sand in the vertical section of the well however in most cases, it doesn’t do much good and only increases the viscosity in the system. This in turn lowers Reynold’s number and makes it harder to move the sand in the horizontal section of the well.

- Depending on the length of the well and the amount of debris seen on the surface it might be worth performing a couple of full wiper trips especially if there are any concerns of sand accumulations in the heel. During a wiper trip, coiled tubing is slowly pulled out of the hole and into the vertical section of the well.

- While running in the well, sand buildups in the wellbore can usually be detected by performing pull tests and watching for any over pulls. Over pull means that the coiled tubing weight becomes more than expected due to debris drag.

- After coiled tubing gets to the target depth, it is usually stopped and a couple of bottom ups are performed to ensure that the well is clean before the coil is pulled to the surface.

Most stuck-in-hole situations occur when the coil is getting pulled to the surface at the end of the job.

That’s why it is a good idea to go slow to ensure that all the debris and sand are brought to the surface instead of getting accumulated in the heel or other sections of the well.

Related: 18 Most Common Coiled Tubing Applications

Cleanouts on Low-Pressure Wells

If the well doesn’t have enough pressure to hold the column of fluid (under pressurized formation) which is common in older wells, nitrogen can be used to lower the hydrostatic pressure in the well.

Usually, cleanouts with nitrogen are more challenging and expensive.

On some extremely low-pressure wells foam can be added to nitrogen to improve lifting efficiency.

The foam, however, needs to be broken down at the surface before the fluid can be disposed of which can complicate the operation and increase the costs.

Instead of pumping continuous foam sometimes pumping foam pills might work as well.

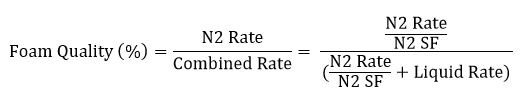

The foam quality is often used to describe the foam stability and suspending capacity.

Higher quality foam works better at suspending particles such as sand in the well.

The foam quality is simply the ratio between the gas volume and the volume of the foam.

N2 Rate (scm/min)

Liquid Rate (m3/min)

N2 SF – N2 space factor

Related: How is Nitrogen Used in the Oil and Gas Industry?

Chemicals Used for Coiled Tubing Wellbore Cleanout Operations

Gel – is used to increase the viscosity of the fluid to improve its lifting capacity in the vertical section of the well.

Metal to metal friction reducer – pumped on the deeper wells where coiled tubing is struggling with getting to the target depth.

Hydraulic friction reducers – are used to decrease pumping pressures.

H2S inhibitors and scavengers – pumped on sour wells.

Biocide – pumped to kill bacteria in the water and protect the coil.

Foamers and defoamers – pumped during nitrogen foam cleanouts.

Surfactants – sometimes pumped to improve fluid’s sand sweeping efficiency.

Read next: How Coiled Tubing Milling Operations Are Performed?